A permanent magnetic lifter is a valuable tool widely used in various industries for lifting and moving heavy objects with ease and safety. Unlike traditional lifting techniques that require manual efforts and potential risks, these magnetic lifters provide a reliable and efficient solution. In this article, we will discuss the operating principle of a permanent magnetic lifter and its significance in different applications.

The principle behind a permanent magnetic lifter relies on magnetism, specifically the concept of a permanent magnet. This lifting device is equipped with multiple powerful permanent magnets that generate a strong magnetic field. The magnets used in these lifters are typically made from rare-earth materials like neodymium, which have exceptional magnetism properties.

When the permanent magnetic lifter is in its inactive state, the magnetic field is contained within the device and does not extend beyond its surface. This ensures the lifter can be safely handled and transported without any unintended lifting or attracting objects. However, when the lifter comes into contact with a ferromagnetic material, such as iron or steel, the strong magnetic field is activated.

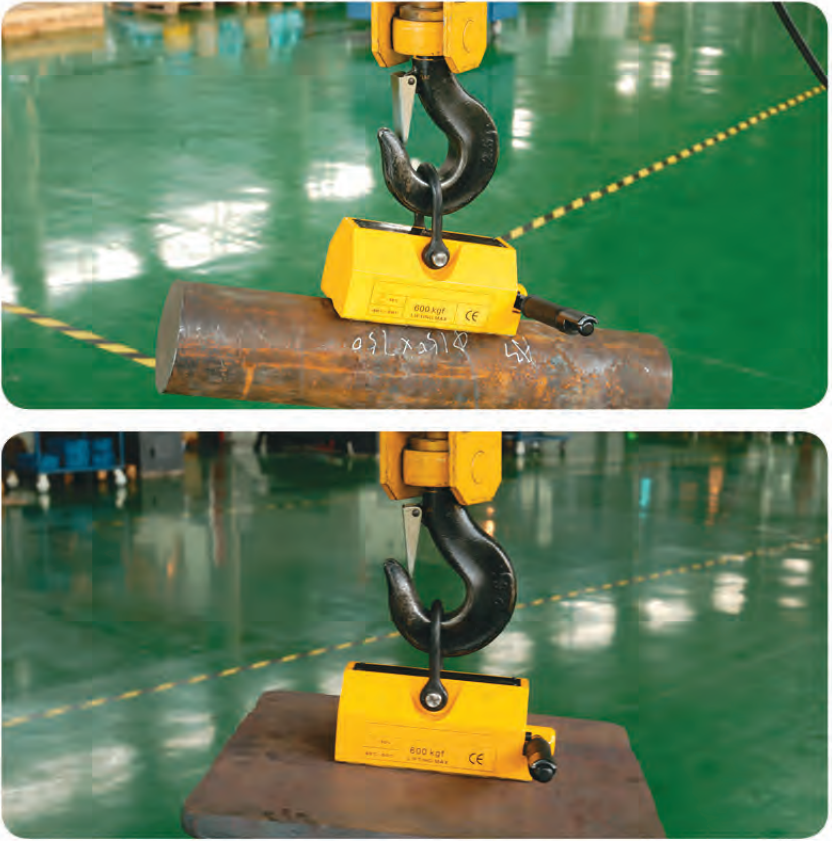

The activated magnetic field of the lifter instantly clamps onto the ferromagnetic object, creating a secure connection. This makes it possible to safely lift and hold heavy loads, ranging from a few kilograms to several tons, depending on the lifting capacity of the lifter. The magnetic force generated by these lifters is strong enough to keep the objects securely lifted, even when subjected to external vibrations or movements.

One of the key advantages of a permanent magnetic lifter is its ability to provide a non-slip grip on the lifted objects. The magnetic force acts directly on the ferromagnetic material, eliminating the need for slings, chains, or hooks that may cause potential damage or instability. This ensures a safe and controlled lifting operation, reducing the risk of accidents or injuries.

Moreover, the operating principle of a permanent magnetic lifter offers significant time and cost savings. Traditional lifting methods often involve labor-intensive processes and additional equipment, while a magnetic lifter simplifies the task by providing a single device for lifting and carrying purposes. This not only improves efficiency but also enhances productivity in various industries such as construction, manufacturing, and shipbuilding.

Additionally, the design of permanent magnetic lifters ensures ease of use. Most lifters feature a compact and lightweight construction, making them portable and suitable for confined spaces or remote areas. They also incorporate a simple yet effective mechanism for activating and deactivating the magnetic field, allowing operators to quickly and safely release the lifted objects by switching off the magnetic force.

In conclusion, the operating principle of a permanent magnetic lifter revolves around the activation of a strong magnetic field by proximity to a ferromagnetic material. This ingenious design allows for efficient and safe lifting of heavy objects while eliminating the need for complex lifting methods. As a result, permanent magnetic lifters have become an indispensable tool in various industries, providing enhanced productivity, safety, and ease of use.

Post time: Oct-20-2023