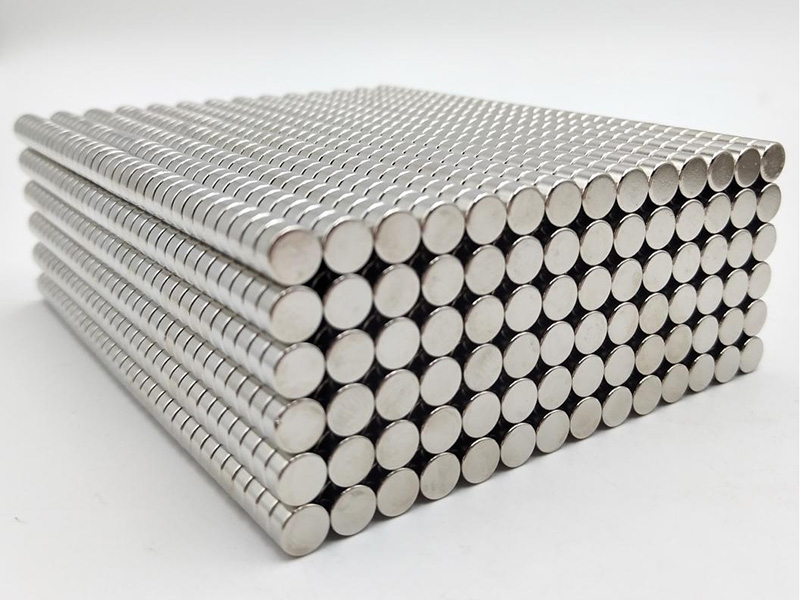

What are Neodymium Magnets

Neodymium magnets (abbreviation: NdFeb magnets) are the strongest permanent magnets commercially available, everywhere in the world. They offer unparalleled levels of magnetism and resistance to demagnetization when compared to Ferrite, Alnico and even Samarium-cobalt magnets.

Neodymium magnets are graded according to their maximum energy product, which relates to the magnetic flux output per unit volume. Higher values indicate stronger magnets. For sintered NdFeB magnets, there is a widely recognized international classification. Their values range from 28 up to 55. The first letter N before the values is short for neodymium, meaning sintered NdFeB magnets.

Neodymium magnets have higher remanence, much higher coercivity and energy product, but often lower Curie temperature than other types of magnets. Special neodymium magnet alloys that include terbium and

dysprosium have been developed that have higher Curie temperature, allowing them to tolerate higher temperatures.The table below compares the magnetic performance of neodymium magnets with other types of permanent magnets.

What’s neodymium magnets used for? Due to neodymium magnets so strongly, their usage are very widely. They are produced for office, commercial and industry needs, which used in types of wind turbines,

speakers, earphones and motors, microphones, sensors, medical care, packaging, sports equipment, crafts and aviation fields.

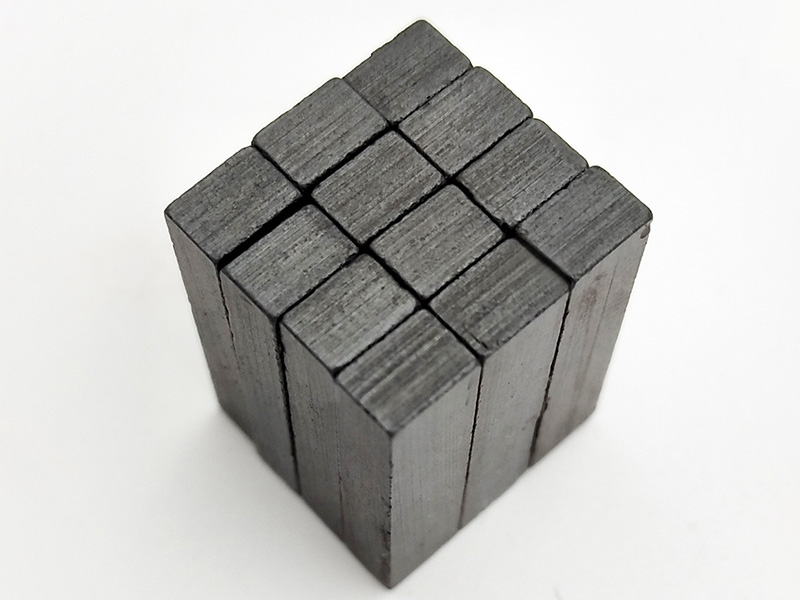

What are Ferrite Magnets

Ferrite Magnets besides hard ferrite magnets and soft magnets.

Hard ferrites have high coercivity, so are difficult to demagnetize. They are used to make permanent magnets for applications such as refrigerator, loudspeakers, and small electric motors and so on.

Soft ferrites have low coercivity, so they easily change their magnetization and act as conductors of magnetic fields. They are used in the electronics industry to make efficient magnetic cores called ferrite cores for high-frequency inductors, transformers and antennas, and in various microwave components.

Ferrite compounds are extremely low cost, being made of mostly iron oxide, and have excellent corrosion resistance.

What Are Alnico Magnets

Alnico magnets are permanent magnets that are primarily made up of a combination of aluminium, nickel and cobalt but can also include copper, iron and titanium.

They come in isotropic, non-directional, or anisotropic, mono-directional, form. Once magnetized, they have 5 to 17 times the magnetic force of magnetite or lodestone, which are naturally occurring magnet materials that attract iron.

Alnico magnets have a low temperature coefficient and can be calibrated for high residual induction for use in high temperature applications as high as 930°F or 500°C. They are used where corrosion resistance is necessary and for various types of sensors.

What are Samarium-cobalt Magnet (SmCo Magnet )

A samarium–cobalt (SmCo) magnet, a type of rare-earth magnet, is a strong permanent magnet made of two basic elements: Samarium and cobalt.Samarium–cobalt magnets are generally ranked similarly in strength to neodymium magnets, but have higher temperature ratings and higher coercivity.

Some attributes of SmCo are:

Samarium-cobalt magnets are extremely resistant to demagnetization.

These magnets have good temperature stability (maximum use temperatures between 250 °C (523 K) and 550 °C (823 K); Curie temperatures from 700 °C (973 K) to 800 °C (1,070 K).

They are expensive and subject to price fluctuations (cobalt is market price sensitive).

SmCo magnets have a strong resistance to corrosion and oxidation resistance, usually do not need to be coated and can be widely used in high temperature and poor working conditions. They are brittle, and prone to cracking and chipping. Samarium–cobalt magnets have maximum energy products (BHmax) that range from 14 megagauss-oersteds (MG·Oe) to 33 MG·Oe, that is approx. 112 kJ/m3 to 264 kJ/m3; their theoretical limit is 34 MG·Oe, about 272 kJ/m3.

Other uses include:

1. High-end electric motors used in the more competitive classes in slotcar racingTurbomachinery.

2. Traveling-wave tube field magnets.

3. Applications that will require the system to function at cryogenic temperatures or very hot temperatures (over 180 °C).

4. Applications in which performance is required to be consistent with temperature change.

5. Benchtop NMR spectrometers.

6. Rotary encoders where it performs the function of magnetic actuator.

Post time: Feb-06-2023