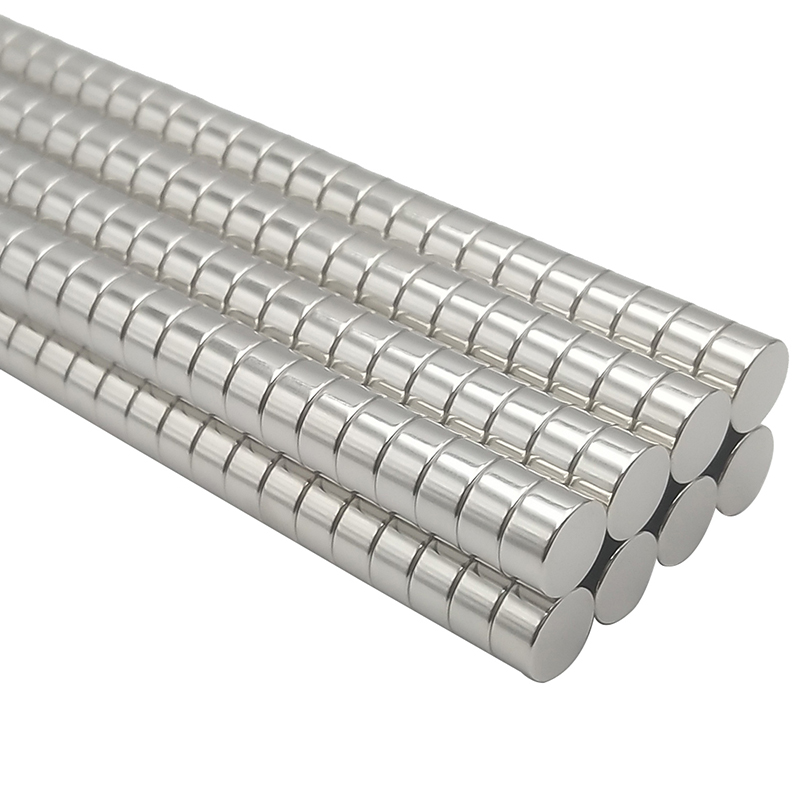

N35 Round Strong Neodymium Iron Boron Magnet

Dimensions: 8mm Dia. x 4mm thick

Material: NdFeB

Grade: N35

Magnetization Direction: Axial

Br:1.17-1.22 T

Hcb:≥ 859 kA/m, ≥ 10.8 kOe

Hcj: ≥ 955 kA/m, ≥ 12 kOe

(BH)max: 263-287 kJ/m3, 33-36 MGOe

Max Operating Temp: 80 °C

Certificate: RoHS, REACH

Product Description

Neodymium magnets are the strongest and most commonly used type of all magnetic alloys. Small, lightweight and super powerful.

Disc NdFeB magnets are used in: sensors, motors, wind turbines, computers, speakers, medical devices, electronics, and many industrial magnet systems.

|

Material |

Neodymium Magnet |

|

Size |

D8x4 mm or as per customers' request |

|

Shape |

Round, Disc / Customized (Block,Disc,Cylinder, Bar, Ring, Countersunk, Segment,hook,cup, Trapezoid, Irregular shapes ,etc) |

|

Performance |

N35 / Customized (N28-N52; 30M-52M;15H-50H;27SH-48SH;28UH-42UH;28EH-38EH;28AH-33AH) |

|

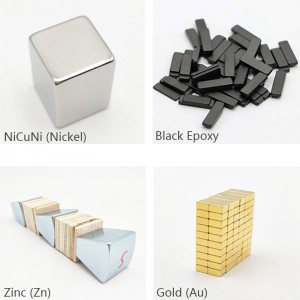

Coating |

NiCuNi, Nickel / Customized (Zn,Ni-Cu-Ni,Ni,Gold, Silver, Copper, Epoxy, Chrome, etc) |

|

Size Tolerance |

± 0.02mm - ± 0.05mm |

|

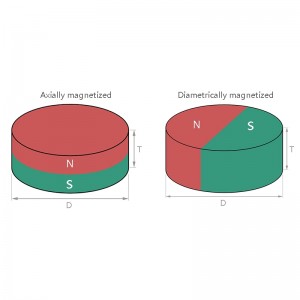

Magnetization Direction |

Axial Magnetized / Diametrally Magnetized |

|

Max. Working |

80°C (176°F) |

Disc Neodymium Magnet Advantages

1.Material

Neodymium magnets have the highest available magnetic energy density, with a (BH)max value of 30 MGOe to 52 MGOe.

This strongest permanent magnet is built from Neodymium Iron Borium - NdFeB.

The use of neodymium magnets in high-tech electronics is very popular because of their high magnetic strength and special performance.

2.World's most precise tolerance

Usually the dimensional tolerance of NdFeB block, round, cylindrical magnet is ±0.05mm, some customers are not strict with the drawings marked ±0.1mm, while for some magnet products that require higher precision we can control to ±0.03mm or even higher.

3.Coating / Plating

Zinc coating provides good adhesion. You will find that the magnets in motors, many of which have a zinc coating, which is used to protect the magnet from corrosion in the surrounding air and to provide mild protection against moisture, water, or salt water. The zinc coating is mainly used for low-temperature applications and where a little protective barrier is required.

4.Magnetic Direction: Axial

The regular magnetic direction of the disc magnet is axially magnetized and diametrically magnetized.

We can magnetize permanent magnets to their saturation level with very powerful magnetization equipment.

Packing & Shipping

Packing: White paper box + Iron plates + Foam + Carton

Shipping: Air, Express, Railway, and Sea transport