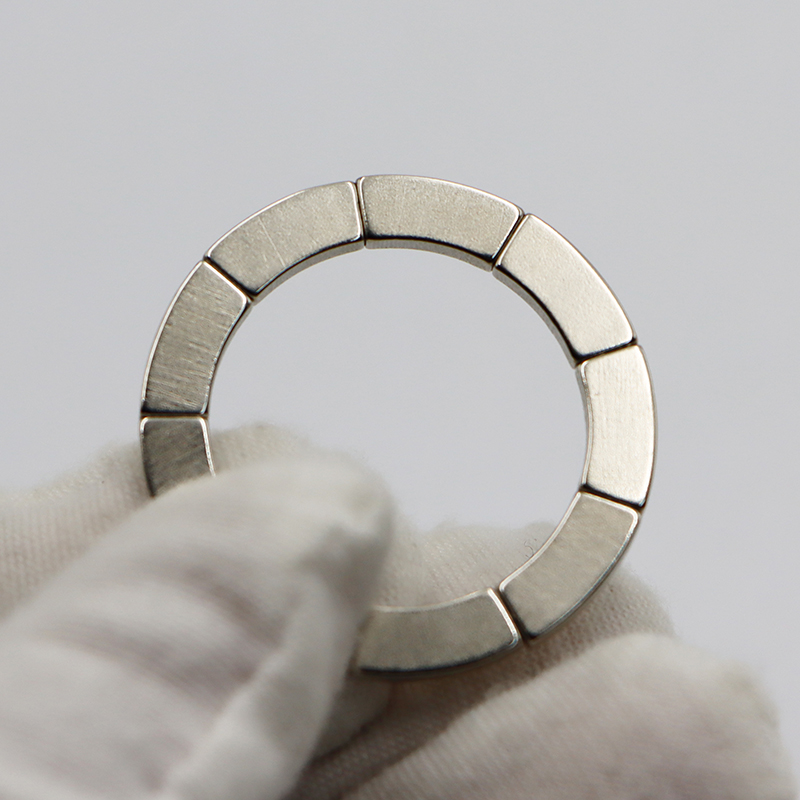

High Performance Arc Curved Neodymium Magnets

Product Description

The Small Arc Neodymium Magnet - a versatile and high-performing product that is designed specifically for precision applications. This powerful magnet is ideal for use in a variety of industries, including electronics, engineering, and manufacturing, and boasts a range of impressive features that make it stand out from other magnet products on the market.

When it comes to motor engineering, the use of high-performance curved neodymium magnets can make a significant difference in the design and operation of motors. Curved magnets, specifically arc NdFeB magnets, offer a range of advantages compared to more traditional magnets, making them an excellent option for motors.

Arc NdFeB Magnet Characteristics

1. High-performance

The first and most significant benefit of using curved neodymium magnets is their high performance. These magnets are constructed from neodymium, a rare earth metal known for its powerful magnetic properties. The use of this material in the construction of curved magnets allows for increased power and efficiency in motor design.

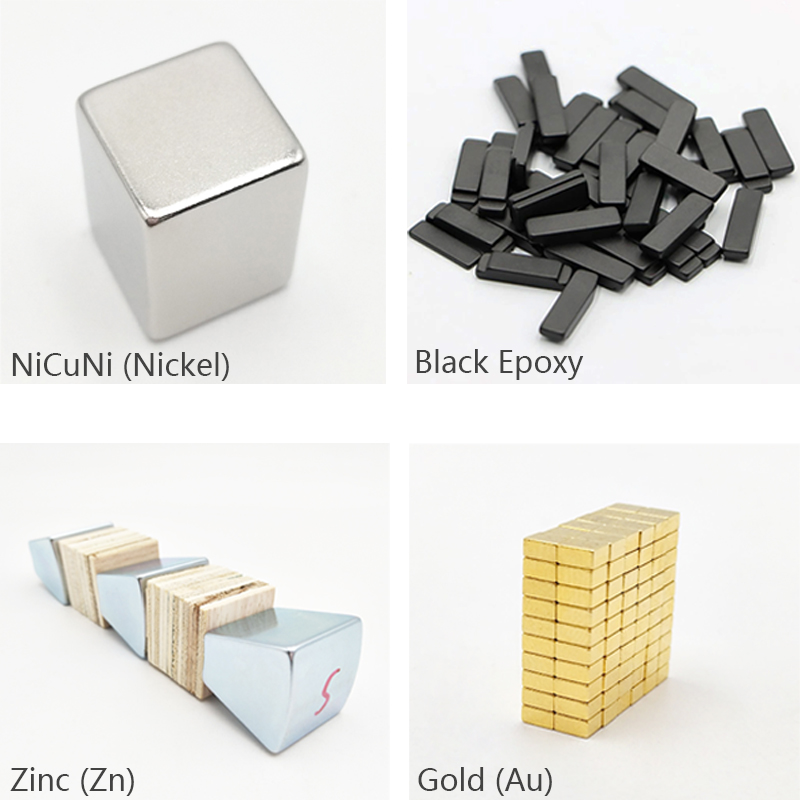

2. Coating / Plating

The NiCuNi coating used on the surface of curved neodymium magnets provides a layer of protection against corrosion and other forms of damage. This allows the magnet to retain its magnetic properties for a longer period of time, making it a reliable option for motor engineering.

Other options: Zinc (Zn) , Black Epoxy, Rubber, Gold, Silver, etc.

3. Pinpoint Accuracy

One of the most significant advantages of using curved neodymium magnets is their level of pinpoint accuracy. The process used to construct these magnets ensures that they are fabricated to very precise specifications, with a tolerance of +/-0.05mm,you can be sure that the position of the magnet will be exactly where you need it to be. This means that they can be used in motors that require extreme accuracy, such as high-speed motors used in the aerospace industry.

Another important advantage of using curved neodymium magnets is their small size. These magnets can be manufactured to incredibly small dimensions, making them suitable for use in a wide range of applications where space is limited. This compact size allows for greater flexibility in motor design, resulting in more efficient and effective products.

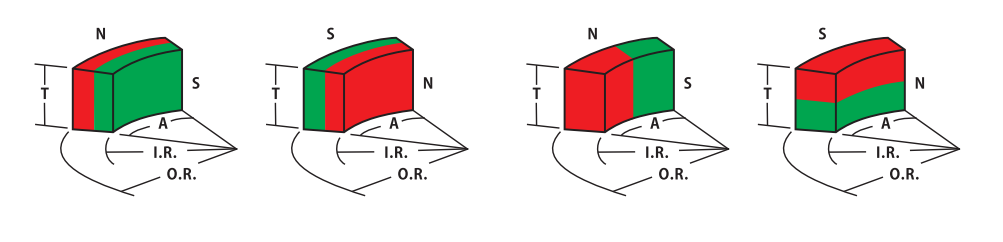

4. Magnetic Direction

Arc magnets are defined by three dimensions: Outer Radius (OR), Inner Radius (IR), Height (H), and Angle.

Magnetic direction of arc magnets: axially magnetized, diametrically magnetized, and radially magnetized.

5. Customizable

In addition to strength and durability, our custom magnets offer versatility. We offer a variety of shapes and sizes, including curved neodymium magnets, to fit specific motor designs.

Packing & Shipping

We usually pack these pot magnets in bulk in a carton. When the size of pot magnets is larger, we use individual cartons for packaging, or we can provide custom packaging according to your requirements.